The 350T and 400T scrap metal shears by DL Industry Group are engineered for excellence, designed to meet the demands of medium to large-scale scrap processing facilities. With robust cutting force and advanced technology, these shears provide the reliability and efficiency you need to maximize throughput and profitability. Tailored for precision cutting and built to withstand continuous operation, our 350T and 400T shears help recyclers, metal fabricators, and demolition contractors streamline operations and manage metal waste effectively.

Heavy-Duty Hydraulic Cutting Power

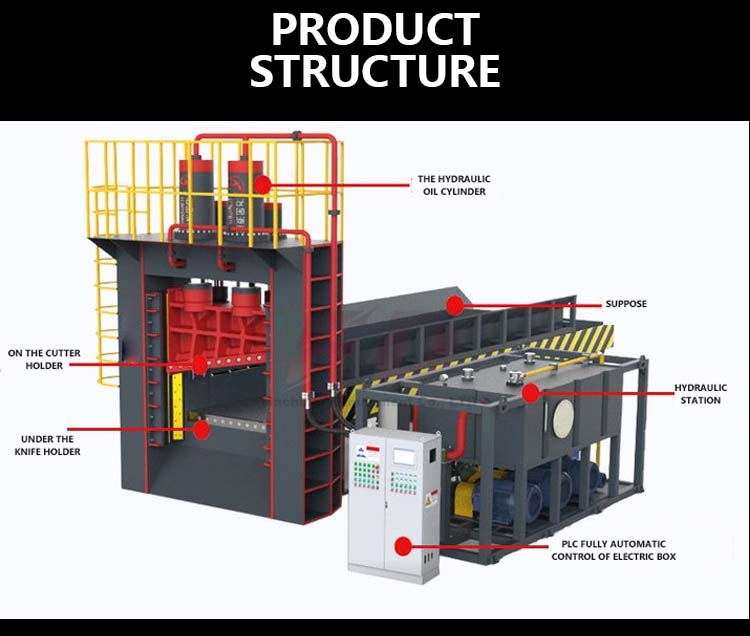

Equipped with a powerful hydraulic system, our 350T and 400T shears effortlessly cut through a wide range of metals. With their high shearing force, these machines handle heavy-duty metal processing with ease, allowing operators to efficiently process steel, aluminum, copper, and other scrap metals.

High Efficiency and Productivity

Designed to maximize productivity, these shears enable faster processing of large metal pieces. Their optimized cycle times reduce downtime and increase operational efficiency, making them ideal for busy scrap yards and industrial recycling facilities that handle high volumes.

Durable Build for Long-Term Use

Built from high-strength steel and reinforced components, the 350T and 400T shears are designed for durability and longevity. With high resistance to wear and tear, these machines deliver reliable performance day after day, minimizing maintenance requirements and maximizing your return on investment.

Precision Cutting Blades

Our shears come with precision-engineered cutting blades capable of producing clean, consistent cuts across various metals and thicknesses. The blades are easy to replace and maintain, keeping your shear operating at peak efficiency with minimal downtime.

User-Friendly Controls

Both the 350T and 400T models feature intuitive controls, making them accessible for operators with varying levels of experience. With user-friendly settings and customizable functions, these shears ensure a smooth and efficient operation, allowing your team to quickly adjust for different types of scrap and cutting requirements.

Enhanced Safety Features

Safety is a top priority, and our shears come with a range of safety features, including emergency stop functions, protective guards, and hydraulic overload protection. These measures help ensure a safe working environment for operators, minimizing the risk of accidents and equipment damage.

Increased Throughput

By integrating our 350T or 400T shear into your operation, you can process scrap more efficiently, increasing throughput and productivity. The robust hydraulic system and high cutting speed mean that more metal can be processed in less time, boosting your operation’s overall output.

Cost-Effective Operations

Our shears are engineered to minimize operating costs. Thanks to their high durability and minimal maintenance needs, the 350T and 400T models offer a low total cost of ownership. They deliver excellent performance over the long term, making them a smart investment for any business looking to cut down on operating expenses.

Versatile for Various Metals

These shears are designed to handle a wide array of metals, from lighter aluminum sheets to thicker steel beams. This versatility allows your operation to process diverse types of scrap, making it easier to meet the demands of various clients and applications.

Environmentally Friendly Solution

Efficiently processing and recycling scrap metal helps conserve natural resources and reduce environmental impact. By investing in high-quality metal shears, you’re not only optimizing your operations but also contributing to a more sustainable future.

The 350T and 400T scrap metal shears are perfect for:

| Feature | 350T Scrap Metal Shear | 400T Scrap Metal Shear |

|---|---|---|

| Shearing Force | 350 Tons | 400 Tons |

| Hydraulic System | normal motor | normal motor or Servo motor |

| Cutting Cycle Time | 20s | 20s |

| Cutting Blade Material | 3-10cm | 3-12cm |

| Machine Weight | 20-35ton | 30-40ton |

| Dimensions | according to requirement | according to requirement |

| Power Requirements | 3 phase input or gas | 3 phase input or gas |

| Safety Features | Emergency stop, overload protection | Emergency stop, overload protection |

For full technical details, please contact our sales team.

At DL Industry Group, we are committed to delivering solutions that empower our clients. With years of experience in designing industrial machinery, we offer products that are built to perform. Our 350T and 400T Scrap Metal Shears are crafted with precision engineering and innovation, ensuring your operation runs smoothly and efficiently.

Our expert team provides exceptional support before, during, and after your purchase. From installation guidance to troubleshooting and maintenance tips, we’re here to help you get the most out of your investment.

Ready to enhance your metal processing operations? Contact us today for a quote, or to learn more about the 350T and 400T Scrap Metal Shears. Our knowledgeable team is available to answer any questions and help you find the perfect shear to meet your needs.

Whatsapp: +8615900363543

Email: leonli@dlindustrygroup.com

Contact: Leon Li (General Sales Director)

Phone: 008615900363543

Tel: 0086-22-84608987

Email: leonli@dlindustrygroup.com

Add: Room 709, Unit 5, Builing 19, Ruihang Square, Dong Er Road, Airport Economic Area, Tianjin, China