For operations requiring robust, heavy-duty solutions, DL Industry Group’s 500T and 800T scrap metal shears offer unparalleled power, precision, and durability. With shearing forces of 500 tons and 800 tons respectively, these models are engineered to handle the toughest scrap metal with ease, making them ideal for high-volume recycling facilities, large-scale demolition projects, and industrial metal processing environments. Built with advanced hydraulic technology and designed to withstand continuous, intensive use, the 500T and 800T shears provide a level of performance that transforms scrap processing efficiency.

Exceptional Shearing Force

With 500-ton and 800-ton shearing capabilities, these machines are designed for high-strength performance, making them suitable for processing thick, heavy metals and oversized scrap materials. This immense cutting power allows operators to tackle challenging projects with confidence, ensuring a consistent output even with dense materials.

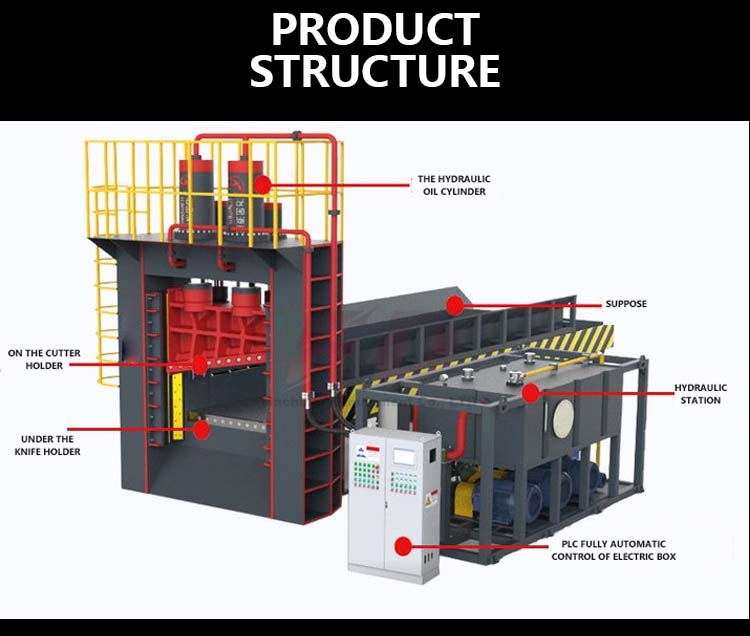

Advanced Hydraulic System

Our 500T and 800T shears are equipped with advanced hydraulic systems that provide smooth, reliable operation under high-pressure conditions. The high-capacity hydraulics enable fast cutting cycles and reduce energy consumption, ensuring that your operations remain efficient and cost-effective over time.

Reinforced Structure for Durability

Constructed from premium-grade steel with reinforced frames, these shears are built to endure continuous heavy use. The reinforced structure minimizes vibrations and enhances stability, allowing for consistent and accurate cutting over prolonged periods without compromising on safety or performance.

Precision-Engineered Cutting Blades

Fitted with hardened steel blades, the 500T and 800T models deliver clean, precise cuts across a wide range of materials and thicknesses. These cutting blades are replaceable and designed for durability, making maintenance easy and helping to maintain peak cutting performance.

Automated and Intuitive Controls

Equipped with an intuitive control system, these models offer operators flexibility with programmable settings and automated options. These controls allow for customized cutting parameters, making it easy to adapt the shear for different scrap types or project requirements without manual adjustments.

Enhanced Operator Safety

The 500T and 800T models prioritize operator safety, incorporating emergency shutoff systems, protective shields, and hydraulic overload safeguards. These built-in safety features are crucial for maintaining a secure environment in fast-paced, heavy-duty operations.

Increased Capacity for Demanding Applications

The high cutting force of the 500T and 800T models makes them ideal for demanding applications, including large-scale scrap processing and the recycling of denser metal types. This capability allows operators to handle higher volumes with fewer cutting cycles, improving overall efficiency.

Enhanced Profitability Through Efficiency

These shears’ advanced hydraulic systems and high cutting speeds mean reduced cycle times and less energy consumption. By maximizing throughput and minimizing downtime, the 500T and 800T shears help boost profitability in metal recycling and processing operations.

Versatile Application Across Metal Types

From heavy-duty steel beams to thicker aluminum and copper scrap, the 500T and 800T shears offer the versatility to cut a wide range of materials. This adaptability makes them valuable assets for scrap yards and metal processors that deal with diverse scrap metal compositions.

Long-Term Cost Savings

Investing in the 500T and 800T scrap metal shears means reducing operational costs over time. The durable build, replaceable cutting blades, and minimal maintenance requirements translate to lower ongoing expenses, providing an exceptional return on investment.

With their superior power and durability, the 500T and 800T shears are well-suited for:

High-Volume Scrap Yards

For scrap yards processing large volumes of diverse metals, the 500T and 800T shears provide the strength and reliability needed to keep operations running smoothly, regardless of material toughness.

Heavy-Duty Recycling Facilities

For industrial recycling facilities that demand efficiency, the 500T and 800T models ensure rapid and consistent processing, making them ideal for heavy-duty operations that handle thicker, bulkier scrap metals.

Industrial and Construction Demolition

These shears excel in demolition applications, easily breaking down structural metal components for removal, recycling, or disposal. With their ability to handle thick beams, pipes, and metal frameworks, these models are indispensable for demolition contractors working on large industrial projects.

Shipbuilding and Marine Salvage

The 500T and 800T shears are also ideal for the shipbreaking industry, where heavy and dense metals need to be quickly cut and processed. Their robust design and high cutting power allow for efficient breakdown of ship structures and other large marine components.

| Feature | 500T Scrap Metal Shear | 800T Scrap Metal Shear |

|---|---|---|

| Shearing Force | 500 Tons | 800 Tons |

| Hydraulic System | High-capacity, efficient | High-capacity, efficient |

| Cycle Time | Optimized for high-volume | Optimized for high-volume |

| Cutting Blade Material | High-strength hardened steel | High-strength hardened steel |

| Machine Weight | Approx. XX tons | Approx. XX tons |

| Dimensions | X m x Y m x Z m | X m x Y m x Z m |

| Power Requirements | Customizable | Customizable |

| Safety Features | Emergency stop, hydraulic overload protection | Emergency stop, hydraulic overload protection |

For more details or specific customization, contact our team for a full technical consultation.

At DL Industry Group, we understand that high-volume and heavy-duty operations require equipment that combines power, reliability, and cost-efficiency. Our 500T and 800T Scrap Metal Shears have been rigorously engineered to meet the needs of the most demanding applications, delivering unmatched performance that boosts your operational efficiency and profitability.

With extensive experience in industrial machinery, DL Industry Group is dedicated to providing solutions that empower our customers to succeed. Our technical support team is available to assist with installation, training, and maintenance, ensuring that you maximize the performance of your new equipment.

Are you ready to upgrade your metal processing capabilities? Contact us today to discuss your requirements or request a quote for the 500T and 800T Scrap Metal Shears. Our experts are on hand to help you find the ideal solution tailored to the needs of your operation.

Whatsapp: +8615900363543

Email: leonli@dlindustrygroup.com

Contact: Leon Li (General Sales Director)

Phone: 008615900363543

Tel: 0086-22-84608987

Email: leonli@dlindustrygroup.com

Add: Room 709, Unit 5, Builing 19, Ruihang Square, Dong Er Road, Airport Economic Area, Tianjin, China