We are focused on the beryllium inorganic substance, metal and alloy including the beryllium metal, beryllium oxide, beryllium fluoride, aluminum beryllium master alloy, beryllium copper master alloy, beryllium copper alloy(C17000, C17200, C17300, C17410, C17500, C17510, JK520, JK38, etc).

Same grade with C17510 beryllium copper alloy in different countries

Other name: Alloy 3, class 3 C17510 beryllium copper, CuNi2Be, C1751 beryllium copper, C17510 beryllium bronze

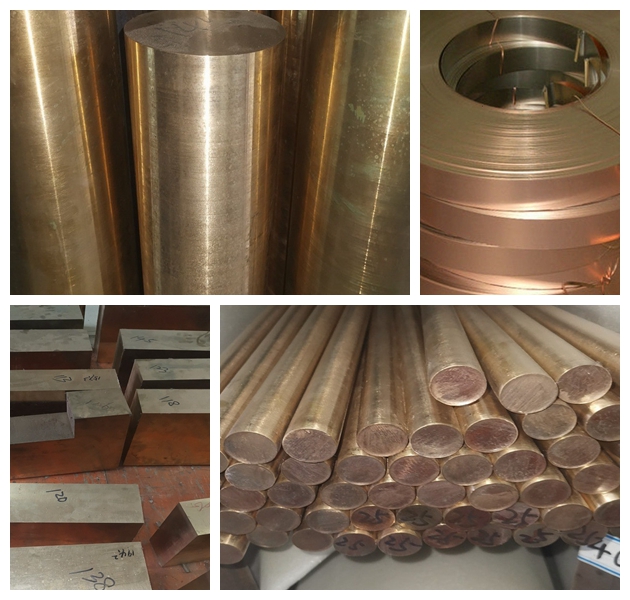

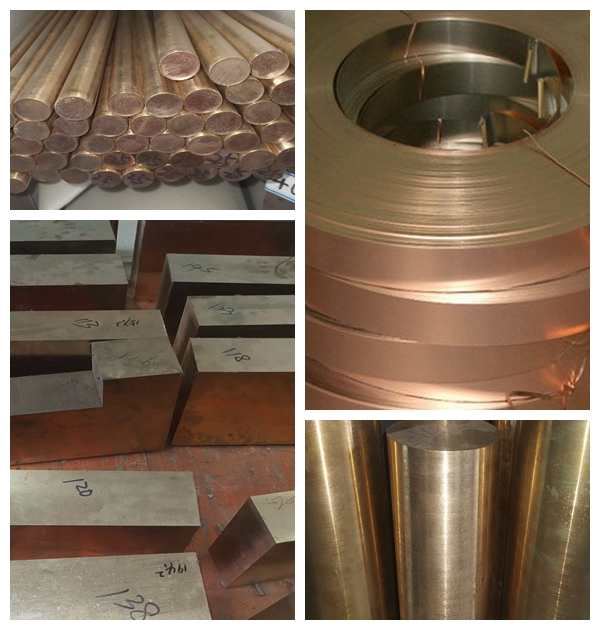

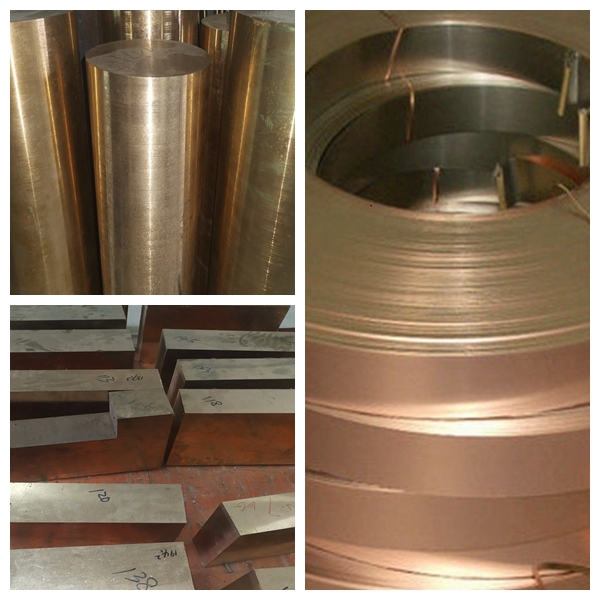

For C17510 Beryllium copper, we can supply as below:

C17510 Beryllium copper rod, C17510 Beryllium copper bar

Diameter (unit: mm): 1.0, 2.0, 3.0, 4.0, 4.5, 5.0, 6.0, 6.5, 7.0, 8, 10, 12, 14, 15, 16, 18, 20, 25, 28, 30, 35, 40, , 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 115, 120, 125, 130, 140, 150, 160, 170, 180, 190, 200,

Length: 1000-2000mm(can produce as customers’ required dimeter)

C17510 Beryllium copper strips, C17510 Beryllium copper coil

Thickness (unit: mm): 0.05, 0.08, 0.1, 0.12, 0.15, 0.2, 0.25, 0.3, 0.35, 0.4, 0.5, 0.6, 0.7, 0.8, 1.0, 1.2(can produce as customers’ required dimeter)

Width: 200mm(can produce as customers’ required dimeter)

C17510 Beryllium copper wire

Diameter (unit: mm): 0.1, 0.12, 0.15, 0.18, 0.2, 0.25, 0.3, 0.35, 0.4, 0.5, 0.6, 0.65, 0.7, 0.75, 0.8, 0.85, 0.9, 0.95, 1.0(can produce as customers’ required dimeter)

C17510 Beryllium copper sheet, C17510 Beryllium copper plate

Thickness (unit: mm): 1.0, 1.5, 1.6, 2.0, 3.0, 4.0, 5.0, 6.0, 8.0, 10, 12, 15, 16, 18, 20, 25, 30, 35, 40, 45, 50, 55, 60, 65, 70, 75, 80, 85, 90, 95, 100, 105, 110, 115, 120, 130, 140, 150mm

Width*length(unit: mm): 400*600(can produce as customers’ required dimeter)

C17510 Beryllium copper tube

Parameter:

|

Grade |

Be |

Co |

Ni |

Co+Ni |

Ti |

Pb |

|

C17200 |

1.8-2.0 |

/ |

/ |

>0.2 |

<0.6 |

/ |

|

C17300 |

1.8-2.0 |

/ |

/ |

>0.2 |

<0.6 |

0.6 |

|

C17410 |

0.15-0.5 |

0.35-0.6 |

/ |

/ |

/ |

/ |

|

C17500 |

0.4-0.7 |

2.4-2.7 |

/ |

/ |

/ |

/ |

|

C17510 |

0.2-0.6 |

|

1.4-2.2 |

/ |

/ |

/ |

Feature of beryllium copper alloy

Beryllium copper alloy combines excellent mechanical properties, physical properties and chemical properties. After heat treatment (solid solution treatment and aging treatment), it has high strength limit, elastic limit, yield limit and fatigue resistance limit comparable to special steel. At the same time, it also has high electrical conductivity, thermal conductivity, high hardness, corrosion resistance, wear resistance, good casting performance, non-magnetic and non-sparking properties on impact, and is widely used in mold manufacturing, machinery, electronics and other industries. No blisters, pores, balanced hardness, dense structure, high strength, good thermal conductivity, good electrical conductivity, corrosion resistance, excellent wear resistance, good processing performance, stable performance under high pressure conditions, non-magnetic, Excellent polishing performance and good anti-adhesive performance.

Physical properties of C17510 beryllium copper alloy:

C17510 beryllium copper alloy is a beryllium bronze alloy, also known as Beryllium Copper 3, with excellent physical, chemical and mechanical properties. Specifically, it has the following characteristics:

1. High strength and hardness: C17510 beryllium copper alloy has extremely high strength and hardness, can withstand high-intensity impact and twisting force, and is not easy to deform and fatigue.

2. High elasticity and wear resistance: C17510 beryllium copper alloy has high elasticity and wear resistance, can withstand long-term use and wear, and is not easy to deform and crack.

3. Good corrosion resistance: C17510 beryllium copper alloy has good corrosion resistance and can be used in various corrosive environments and is not prone to rust and corrosion.

4. High conductivity: C17510 beryllium copper alloy has high conductivity and can be used to manufacture various high-precision, high-reliability electronic components and electrical connectors.

5. Non-magnetic: C17510 beryllium copper alloy is a non-magnetic material and can be used to manufacture equipment and instruments that require anti-magnetic interference.

6. Impact does not produce sparks: C17510 beryllium copper alloy does not produce sparks when impacted or rubbed, and can be used to manufacture equipment and tools in flammable and explosive places.

To sum up, C17510 beryllium copper alloy is an advanced elastic material with excellent performance. It is widely used in aviation, aerospace, electronics, communications, machinery and other fields to manufacture various high-precision and high-reliability parts and components.

We produce and supply other Beryllium Copper Master Alloy

Beryllium Copper Master Alloy CuBe4.0(Be: 3.8-4.3)

Beryllium Copper Master Alloy CuBe4.0(Be: 3.8-4.3)

Beryllium Copper Ingot

Beryllium Copper Master Alloy CuBe10.0(Be>9.8)

Beryllium Copper Master Alloy CuBe10.0(Be>9.8)

Beryllium Copper Ingot

C17200 beryllium copper alloy

C17200 beryllium copper alloy

in sheet, coil, strip, rod

C17300 beryllium copper alloy

C17300 beryllium copper alloy

in sheet, coil, strip, rod

C17510 beryllium copper alloy

C17510 beryllium copper alloy

in sheet, coil, strip, rod

in powder

Aluminum Beryllium Master Alloy AlBe3

Aluminum Beryllium Master Alloy AlBe3

Aluminum Beryllium Ingot

Aluminum Beryllium Master Alloy AlBe5

Aluminum Beryllium Master Alloy AlBe5Aluminum Beryllium Ingot

Contact: Leon Li (General Sales Director)

Phone: 008615900363543

Tel: 0086-22-84608987

Email: leonli@dlindustrygroup.com

Add: Room 709, Unit 5, Builing 19, Ruihang Square, Dong Er Road, Airport Economic Area, Tianjin, China